Here are some common inventory issues we get asked about here at ShipHero, and my tips for how growing e-commerce businesses can deal with them.

Juggling multiple inventory numbers

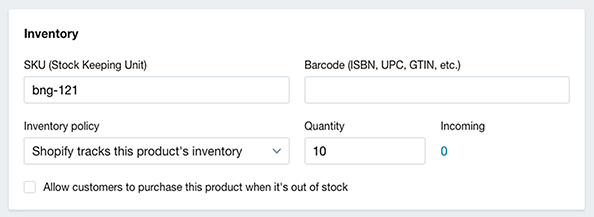

If you sell on several e-commerce platforms, the platform will track the “quantity” of the product. This is what that looks like in Shopify, for instance.

In the example above, you have a quantity of 10. When a customer orders one unit, you’d expect to have a quantity of 9. Except when you check the stock on your shelf, you still have 10. This is because you haven’t shipped that order yet. If you update Shopify to have 10 based on what you have on your shelf, you’ll eventually ship that order and will end up listing one more unit than you actually have.

The result? When the tenth person orders that item, you won’t have it – and you won’t know why. This will lead to a lot of wasted effort trying to find the item and eventually to upset customers because you can’t fill their orders.

The solution to this common inventory headache is to separate what you have available for sale from what you have in stock.

At the simplest level that means tracking “On Hand” inventory (what’s on the shelf) and “Allocated” inventory (what you owe customers). You then tell your e-commerce platform what you have Available, a number that is On Hand minus Allocated.

In practice, you’ll want to track several other inventory components, which also include Backorder, Reserved and Sell Ahead.

Backorder: Backorder is how many units you owe to customers for open orders and don’t have stock for in the warehouse.

Reserved: Reserved is stock inventory you’ve set to not be sold on your platform. For example, if you’re running a flash sale and want to hold some stock for returns or exchanges, you’d enter your full inventory of, say, 100 units as the On Hand and a Reserved of 5 units. We’ll then tell the platform that you have 95 available for sale (On Hand minus Reserved). The Available, however, will remain 100.

Sell Ahead: Sell Ahead is stock that is coming in on a Purchase Order that you want to sell on your platform but that has not yet been received. For example, if you have 10 On Hand, 0 Allocated and a Purchase Order coming in tomorrow with 100 units, you might set a Sell Ahead of 50 of those units. From there, we’ll tell the platform that you have 60 for sale (Available plus Sell Ahead).

Stay in the loop. Get the latest e-commerce tips, resources and news delivered right to your inbox.

Sign up nowLosing items in the warehouse can be costly

If you don’t have good binning and receiving policies, and you’ve moved your warehouse along the way, you’ve undoubtedly found products that had been lost for months or even years. That’s lost revenue and wasted space.

Inventory gets lost in one of two ways.

- The item comes into the warehouse and is put away, but the quantity received isn’t properly recorded. The result: you simply never sell those units because you think you don’t have them.

- You record that you received the products, but can’t find them in the warehouse. Therefore, when a customer orders, you can’t locate the product to fulfill the order and eventually cancel the order and set your stock to 0 – even though you actually have stock.

To resolve this dilemma, always receive on digital purchase orders and always scan into locations.

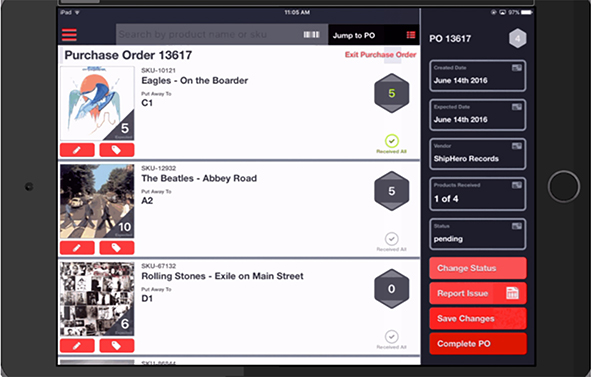

Receiving on digital purchase orders

Before items arrive at the warehouse, be sure you have a digital record of what’s expected. The warehouse simply confirms that what was expected arrives, with any adjustments for over and under received, and closes the purchase order (PO). This updates your internal inventory count to include what was received. If a PO isn’t received, it’s very obvious – you will have an old open PO that you can resolve with no risk of stock that came in not being recorded.

Scanning into locations

All locations in the warehouse should have bin barcodes. When a new item is received you scan the bin barcode, and when an item is moved the bin barcode at the new location is scanned. The history should be recorded. If any item shows as in stock, but with no bin location, it’s immediately evident and can be rectified quickly – before the warehouse staff can no longer recall what happened.

Smart inventory management is essential to your business. Use these techniques to take control of your operations and prevent those potential money leaks.

Aaron Rubin founded and was the CEO of a mid-size ecommerce company for 14 years. After struggling to find a warehouse management solution (WMS) that provided the efficiency, accountability and ease of use needed at a reasonable cost, he founded ShipHero, a robust WMS for ecommerce small-to-mid-size businesses. ShipHero is a Canada Post partner.

Solutions that drive success

Discover our solutions that help drive business efficiency and satisfied customers.

Contact an expert