David Kang has led fulfillment strategies across a variety of organizations and knows the ins and outs of moving warehouses, increasing efficiencies and managing storage capacities. His strength lies in working with retailers who have experienced exponential growth in their e-commerce business.

David Kang has led fulfillment strategies across a variety of organizations and knows the ins and outs of moving warehouses, increasing efficiencies and managing storage capacities. His strength lies in working with retailers who have experienced exponential growth in their e-commerce business.

When running a busy e-commerce company, it’s easy to just do what gets the orders out the door and not consider how to make your operations more efficient. Be it in your basement or back of your physical retail space, it’s worth asking: is your existing fulfillment space still doing the job? Can you find what you need, when you need it? Do you need outside help or simply more space?

The answer, of course, is “it depends.” When considering expanding your fulfillment strategy to a warehouse space, consider that in-house warehouse management (i.e. doing it yourself) gives you total control of your distribution processes. By keeping everything in-house, you can control the quality, protect the brand, and personally connect with customers.

On the other hand, using an established third party logistics (3PL) provider gives your company access to a host of logistical solutions that can help you scale space, labour, and transportation according to inventory needs, particularly during seasonal periods.

While there are clearly several options for merchants looking to expand their fulfillment operations through a third party, here are a few considerations for those looking to run their own warehouse operation.

When is it time to make a move?

When is the right time to consider making the leap from your current fulfillment space to a warehouse? “When you can’t find what you need, or there’s no room to walk down the aisles anymore, you need to take a closer look at expanding your space,” explains fulfillment expert David Kang.

Modifying any part of the supply chain can mean a big change for growing e-commerce enterprises, Kang warns. To create an error-free, structured and efficient system, it’s important that merchants understand what stage their business is in, and how a modified fulfillment model will either help them evolve or at least offer a more immediate competitive advantage.

How much space do we really need?

The actual length, width and height of the warehouse will depend on how much inventory you carry, the number of SKUs you stock, the amount of product you receive and ship daily, and how it all moves in and out.

In determining the amount of space needed for all such functions, you’ll want to make good use of the total square footage of the building, and not just the floor area. “You’re not paying for the parking lot, so put the garbage and recycling outside,” Kang suggests. “Use the space to house inventory that creates value.”

Some other things to consider are aisle widths, the number of loading doors, bay heights for shipping trucks, and overhead lighting.

Stay in the loop. Get the latest e-commerce tips, resources and news delivered right to your inbox.

Sign up nowHow much are we planning to store?

Most e-commerce warehouses have pallet-sized racking for bulk storage, and pickable shelving sized for human arms to select one item at a time to fulfill online shoppers’ orders. When determining your space needs, use the standard pallet size (48/40/48) to visualize how many you would need to fit into your space. From there, you can determine your racking costs. Since most leases run from three to five years, be sure to plan for continued growth, breaking down expected expansion in sections over the life of the lease.

Looking ahead, Kang expects basic rack and shelving construction to remain fairly constant, but feels more of these products will be customized and engineered to meet the needs of specific customers.

Where do we really want to be?

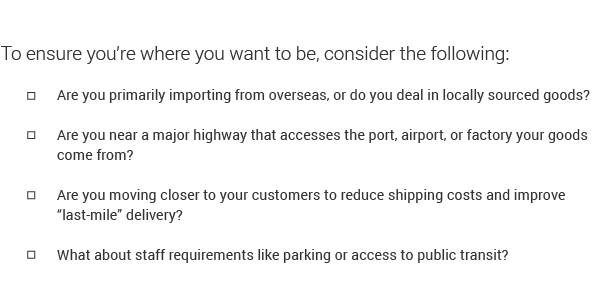

There was a time when warehouses and distribution centers were found in remote locations, where costs for land, labour and taxes were lower. But many e-commerce companies are considering “infill” locations – sites within urban areas that might be repurposed as distribution centres – as alternatives.

Depending on the nature of your particular e-commerce business, and what you intend to do with the new space, your warehouse’s location should be driven by several important factors, including where your goods originate, Kang notes.

Today’s warehouse has evolved from its basic function as a storehouse, to a flexible component of the entire global supply chain.

Who are we going to hire?

How easy will it be for you to hire and train an expanded workforce to run your new warehouse? You may only need one or two more people initially, but depending on the size of your staff and the qualifications required, an increase in numbers could have other implications on your business.

You also need to have a plan in place to deal with seasonality, particularly around the holidays, Kang suggests. Don’t be in a rush. Contemplating a move while dealing with a glut of orders during the high season can lead to irreparable gridlock, he warns. Take the time when sales are steady to look over last year’s sales data and draw up a sensible timetable.

How long are we likely to stay?

Get an idea of market rents in the neighbourhood you’re considering and compare them with the landlord’s asking rent. Talk to a commercial realtor to get up-to-date market lease rates. That information will help you negotiate a favourable deal.

Besides the base square footage cost, the length of your lease is another primary issue to consider. The wrong term can act like a slow leak in your tires, and can leave the door open to huge costs if the unexpected happens.

If you’re uncertain about near-term needs, consider a shorter lease – two or three years, for example. “You’ll likely pay more per square foot for a shorter lease, but at least you can walk away more readily if you need to,” Kang says. “You need a ripcord if things don’t go well.”

At the same time, be sure to understand when and how the lease will be renewed if your plans bear fruit. You may be able to negotiate other hedging options, such as the right of first refusal to lease an adjoining unit for expansion.

Enlist the aid of other merchants

With so many factors at work, establishing or expanding your warehouse can be a bit intimidating, Kang admits: “But you don’t have to fly solo. Lean on other merchants and warehouse supply vendors in the community to help you get started. I’ve found people are happy to talk about their experiences – in particular where they might have gone wrong.”

Solutions that drive success

Discover our suite of solutions that help drive business efficiency and satisfied customers.

Contact an expert